Hydroxypropyl Methylcellulose (HPMC) is a non-ionic, water-soluble polymer material derived from natural cellulose through etherification modification. Due to its stable structure, adjustable properties, and strong application adaptability, HPMC has been widely used in various industries, including building materials, pharmaceuticals, food, daily chemicals, and coatings, becoming an important category of functional additives.

Multifunctional Properties of HPMC

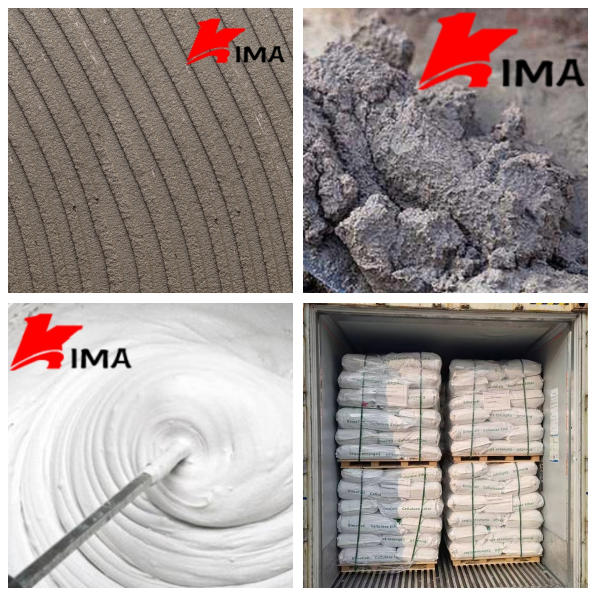

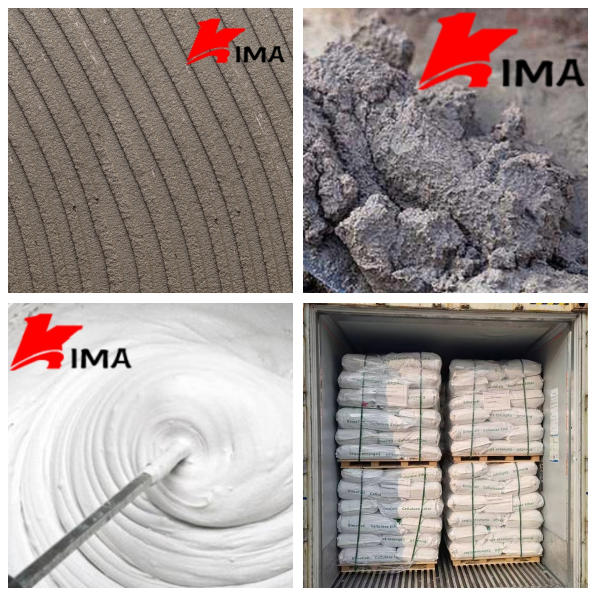

HPMC exhibits excellent thickening and rheological control capabilities. When dissolved in water, it forms a uniform, transparent, high-viscosity solution. By adjusting the degree of substitution and viscosity grade, the fluidity, thixotropy, and workability of the system can be precisely controlled. This characteristic makes it particularly effective in mortar, coatings, and adhesive systems.

HPMC has good water retention properties. The hydrophilic groups in the HPMC molecule can effectively bind free water, slowing down water migration and evaporation, thereby extending the working time of the material, improving the hydration completeness of cement-based materials, and preventing problems such as cracking and delamination caused by early water loss.

HPMC possesses film-forming and bonding auxiliary properties. During the drying process, HPMC can form a continuous, flexible polymer film, improving the surface quality of the material and enhancing the cohesion and stability of the system. This characteristic is particularly important in drug coating, food coatings, and paint applications.

HPMC also exhibits good thermogelation and chemical stability. Its aqueous solution undergoes reversible gelation under heating conditions, maintaining structural stability within a certain temperature range; at the same time, it has strong resistance to acids, bases, and salts, making it suitable for a variety of complex formulation systems.

Main Industrial Applications of HPMC

In the building materials field, HPMC is a key additive in dry-mix mortars, tile adhesives, plaster mortars, and self-leveling mortars. By improving water retention, workability, and anti-sagging properties, it significantly improves the construction efficiency and finished product quality of building materials.

In the pharmaceutical industry, HPMC is widely used as a pharmaceutical excipient, such as a tablet binder, sustained-release matrix material, and capsule shell raw material. Its non-toxic, non-irritating, and controllable swelling properties enable the stable release of drugs, improving drug safety and efficacy. In the food industry, HPMC is commonly used in baked goods, emulsified systems, and plant-based foods, acting as a thickener, stabilizer, shaping agent, and texture enhancer, while also complying with food safety regulations.

In the daily chemical and coatings industries, HPMC can be used as a rheology modifier and stabilizer in products such as detergents, emulsions, and latex paints, improving system stability, brushability, and storage performance.

With its multiple functions including thickening, water retention, film formation, and stabilization, HPMC has established a highly flexible application system. As industrialization in the construction industry, advancements in pharmaceutical formulations, and the demand for green materials continue to grow, the performance optimization and application depth of HPMC will continue to expand, demonstrating broad development prospects in various industries.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland