In modern construction, methyl hydroxyethyl cellulose (MHEC) is widely used as a high-performance functional additive in various building materials such as mortar, plaster, dry-mix mortar, and insulation materials. Choosing the right construction-grade MHEC can significantly improve construction performance and increase the service life and efficiency of building materials. However, the market offers a wide variety of MHEC products with significantly different performance parameters. Choosing the right product requires comprehensive consideration of the following aspects.

Clarify Construction Requirements

The first step in choosing an MHEC additive is to clarify the construction process and material requirements. Different building materials have different performance requirements for MHEC:

Mortar and plaster: Require MHEC to have good water retention, moderate fluidity, and extended open time to ensure that the mortar does not dry and crack during construction, while also facilitating construction operations.

Dry-mix mortar: Emphasizes rheological control and water retention. The addition of MHEC can improve the stability and ease of application of dry-mix mortar, while also enhancing its trowelability.

Insulation materials or lightweight mortar: Require MHEC to have high bonding strength and a certain thickening effect to ensure that the material remains lightweight without reducing adhesion.

Clarifying requirements helps narrow down the selection range and avoids blindly pursuing a single performance aspect that may negatively impact overall results.

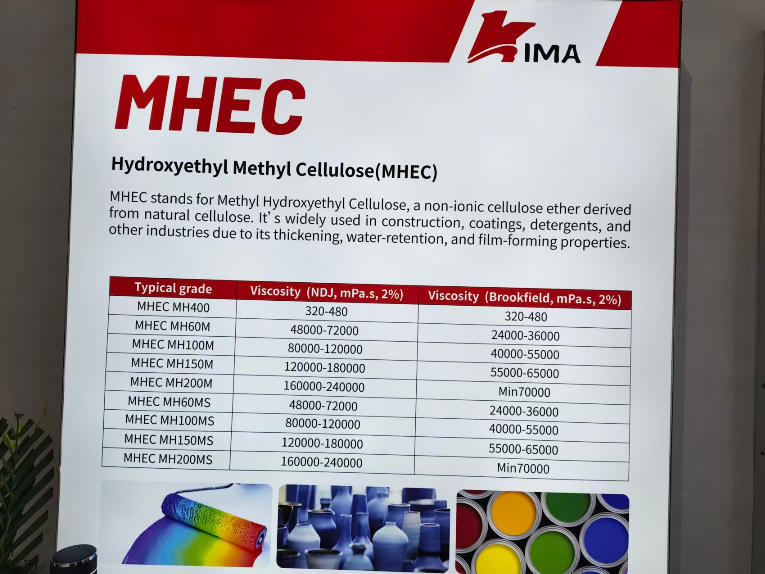

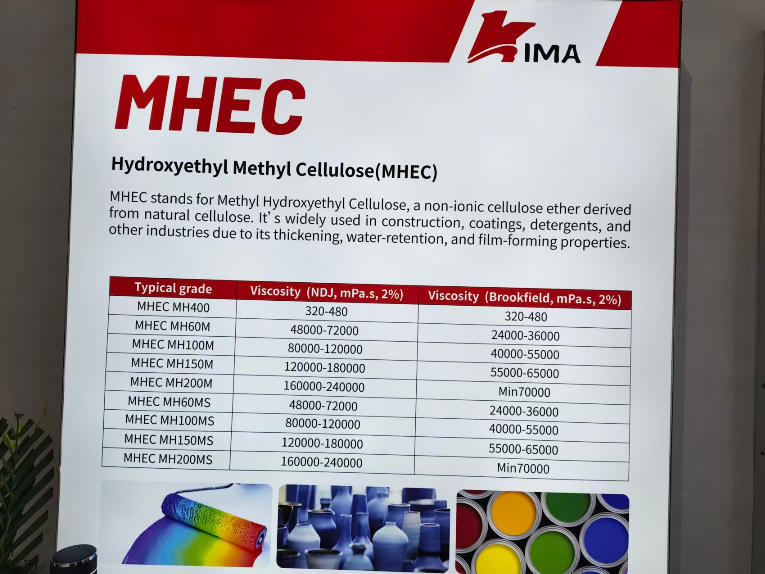

Consider Viscosity and Substitution Degree

Viscosity: Higher viscosity results in greater material consistency, better support and water retention during construction, but may reduce fluidity; excessively low viscosity results in insufficient water retention and workability. Generally, medium-viscosity MHEC is suitable for conventional mortars, while high-viscosity MHEC is more suitable for lightweight insulation mortars.

Methyl/hydroxypropyl substitution degree: Higher substitution degree leads to better water solubility and stronger water retention, but excessively high levels may reduce construction fluidity. When choosing, it should be matched to the water absorption of the construction material and the construction thickness to ensure smooth construction without mortar collapse or cracking.

Consider Rheological Control Capabilities

Building materials require certain rheological control capabilities during construction to ensure ease of application and post-construction performance. High-quality MHEC can regulate the shear-thinning properties of mortar, making it easy to handle during mixing and troweling, while maintaining a stable form when at rest, preventing settling or segregation. This is especially important for wall plastering or thermal insulation mortar, directly affecting construction quality and surface smoothness.

Emphasis on Water Retention and Crack Resistance

The water retention effect of MHEC in mortar is crucial. It extends the hydration time of the mortar, reduces early drying shrinkage, and thus lowers the risk of cracking. When selecting MHEC, it is necessary to pay attention to its water retention effect in actual construction. This can be determined through experiments measuring the change in water content and cracking of the mortar, selecting a product with water retention properties that match the construction requirements.

Consideration of Construction Environment and Methods

Different construction environments (such as high temperature, dry or humid conditions) require different adaptability from MHEC:

In high-temperature and dry environments, high water retention MHEC is needed to prevent the mortar from drying too quickly.

In humid or low-temperature environments, a product with moderate water retention and good fluidity can be selected to ensure ease of construction.

At the same time, the construction method (manual application, spraying, or mechanical application) will also affect the selection of MHEC. For example, sprayable mortar requires MHEC with good adhesion and spray rheological properties to ensure that the material does not flow back or peel off.

Balancing Economy and Stability

While meeting construction needs, reasonably evaluate the cost-effectiveness of MHEC. High-performance MHEC is more expensive, but it has significant advantages in improving construction efficiency, reducing rework rates, and ensuring material performance. At the same time, a supplier with a stable source and reliable quality should be chosen to ensure consistent performance over long-term use and avoid fluctuations in construction quality due to batch differences.

Selecting the appropriate construction-grade MHEC additive requires comprehensive consideration of factors such as the type of construction material, viscosity and degree of substitution, rheological control, water retention, construction environment, and economics. By clarifying needs, conducting scientific experiments, and utilizing supplier technical support, it is possible to select an MHEC product that is stable in performance, easy to use, and cost-effective, thereby optimizing the performance of building materials, improving construction quality, and enhancing building durability. Proper selection is not only a prerequisite for ensuring material performance but also an important link in improving construction efficiency and controlling project quality.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland