How HPMC Improves Water Retention and Workability in Plastering Mortar Systems

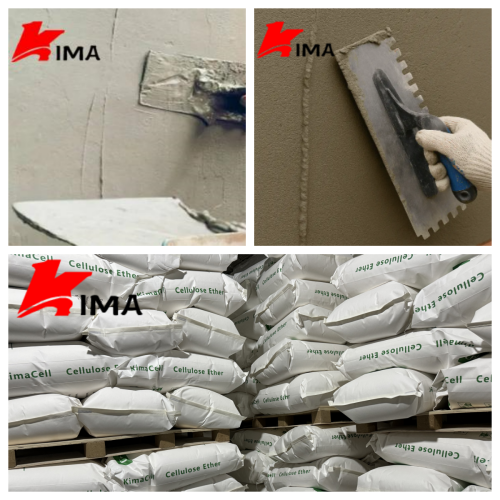

Hydroxypropyl methylcellulose (HPMC) is a key functional additive in plastering mortar formulations, widely used to enhance water retention and workability. These two properties are critical for ensuring smooth application, strong adhesion, and consistent curing performance in both hand-applied and machine-applied plastering systems.

One of the primary functions of HPMC is its excellent water retention capability. During plastering, cement hydration requires sufficient water to proceed effectively. Without adequate water retention, moisture can be rapidly absorbed by porous substrates or lost through evaporation, leading to premature drying. HPMC forms a thin, protective polymer film within the mortar matrix, slowing down water migration and evaporation. This controlled release of water ensures complete cement hydration, resulting in improved strength development and reduced risk of surface defects such as powdering or shrinkage cracks.

In addition to water retention, HPMC significantly improves the workability of plastering mortar. When dispersed in water, HPMC increases the viscosity of the fresh mix and creates a stable, lubricating effect between solid particles. This lubrication reduces internal friction, making the mortar easier to mix, spread, and level. Applicators benefit from smoother troweling, better cohesion, and extended open time, which is especially important for large-area plastering and high-temperature construction environments.

HPMC also contributes to a more uniform and consistent mortar structure. By stabilizing the distribution of water and fine particles, it prevents segregation and bleeding during application. The mortar maintains a creamy, cohesive texture that adheres well to vertical surfaces without excessive sagging. This improves construction efficiency and reduces material waste caused by rework or drop-off.

The incorporation of HPMC in plastering mortar systems leads to improved application performance, enhanced curing conditions, and more reliable final results. By optimizing both water retention and workability, HPMC plays a vital role in achieving high-quality plaster finishes and long-term durability.

The Effect of HPMC on Rheology Control, Consistency, and Anti-Sag Performance

Hydroxypropyl methylcellulose (HPMC) plays a crucial role in controlling the rheological behavior of plastering mortar, directly influencing consistency, stability, and anti-sag performance. Proper rheology is essential for achieving smooth application, good build-up on vertical surfaces, and uniform thickness without material slippage.

HPMC acts as a rheology modifier by increasing the viscosity of the fresh mortar and introducing a pseudoplastic, or shear-thinning, flow behavior. Under shear stress—such as mixing, pumping, or troweling—the mortar becomes less viscous and flows easily, allowing for smooth spreading and efficient application. Once the shear force is removed, the viscosity quickly recovers, enabling the mortar to remain in place on walls or ceilings. This balance between flowability and structural stability is a key advantage of HPMC-modified plastering mortars.

Consistency control is another important benefit provided by HPMC. By regulating water distribution within the mix, HPMC helps maintain a uniform and predictable mortar texture from batch to batch. This consistency ensures stable performance during application, reduces sensitivity to minor water dosage variations, and improves on-site reliability. Applicators experience a creamy, homogeneous mortar that responds well to finishing operations, resulting in smoother surfaces and improved workmanship.

Anti-sag performance is particularly critical in vertical and overhead plastering applications. HPMC enhances the internal cohesion of the mortar, increasing its yield stress and resistance to gravitational flow. This prevents sagging, slumping, or sliding after application, even when applied in thicker layers. Improved anti-sag properties allow for greater layer build-up in a single pass, increasing productivity and reducing labor time.

HPMC helps stabilize entrained air and fine particles within the mortar system, minimizing segregation during application. This further supports rheological stability and ensures uniform performance throughout the working time. Overall, through precise rheology control, improved consistency, and effective anti-sag behavior, HPMC enables plastering mortars to achieve superior application performance and high-quality surface results.

HPMC Contribution to Adhesion Strength, Surface Smoothness, and Crack Resistance

Hydroxypropyl methylcellulose (HPMC) is an essential additive in plastering mortar that significantly enhances adhesion strength, surface smoothness, and crack resistance. These performance improvements are critical for achieving durable, high-quality plaster finishes that meet both construction and aesthetic requirements.

HPMC improves adhesion strength primarily through its water retention and film-forming properties. By retaining sufficient moisture in the fresh mortar, HPMC ensures continuous cement hydration at the interface between the mortar and the substrate. This leads to better bonding with common surfaces such as concrete, masonry, and gypsum-based backgrounds. Additionally, the polymer film formed by HPMC increases the contact area and cohesion between mortar particles and the substrate, reducing the risk of debonding or hollowing after curing.

Surface smoothness is another key benefit of incorporating HPMC into plastering mortar. The improved rheological behavior and lubrication effect provided by HPMC allow the mortar to spread evenly and respond smoothly to troweling. Fine particles are uniformly suspended, preventing dragging, tearing, or uneven texture during finishing. As a result, the plastered surface appears flatter, denser, and more refined, often reducing the need for additional finishing or surface correction.

Crack resistance is closely linked to HPMC’s ability to control moisture loss and shrinkage. Rapid water evaporation or uneven drying can cause internal stresses that lead to microcracks or visible surface cracking. HPMC slows down water loss and promotes gradual, uniform drying, minimizing shrinkage stresses within the hardened mortar. Furthermore, the improved internal cohesion and flexibility introduced by HPMC help the mortar accommodate minor substrate movements and thermal changes.

By enhancing adhesion strength, improving surface smoothness, and reducing crack formation, HPMC contributes to the long-term durability and visual quality of plastering mortar systems. Its multifunctional role makes it a key component in modern plaster formulations designed for reliable performance and superior finishing results.

Selecting the Right HPMC Grade for Different Plastering Mortar Formulations and Application Conditions

Choosing the appropriate Hydroxypropyl methylcellulose (HPMC) grade is essential for optimizing the performance of plastering mortar under different formulation requirements and construction conditions. HPMC grades vary in viscosity, substitution level, particle size, and dissolution behavior, all of which directly influence mortar workability, water retention, and application performance.

Viscosity is one of the most important parameters when selecting an HPMC grade. Low- to medium-viscosity HPMC grades are typically used in thin-layer or fine plastering mortars where good flowability and smooth finishing are required. These grades provide sufficient water retention without excessively increasing viscosity, allowing for easy spreading and fine surface texture. High-viscosity HPMC grades are more suitable for thicker plaster layers or rough base coats, as they offer stronger water retention, enhanced anti-sag properties, and better build-up on vertical surfaces.

Application method also plays a critical role in grade selection. For hand-applied plastering mortars, HPMC grades with balanced thickening and good workability are preferred to ensure smooth troweling and extended open time. In contrast, machine-applied or spray plastering systems often require HPMC grades with controlled dissolution and stable rheology to support pumping performance, prevent clogging, and maintain consistency during continuous application.

Environmental conditions should also be considered. In hot, dry, or windy climates, higher water retention HPMC grades help reduce rapid moisture loss and prevent premature drying. In cooler or more humid conditions, lower-retention grades may be sufficient and can help maintain appropriate setting times.

Compatibility with other additives such as redispersible polymer powders, air-entraining agents, and retarders must be evaluated. A well-matched HPMC grade ensures synergistic performance without negative interactions. By carefully selecting the right HPMC grade based on formulation design, application method, and site conditions, plastering mortar manufacturers can achieve consistent quality, improved efficiency, and durable finishing results.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland