Carboxymethyl cellulose (CMC) is a water-soluble polymer derived from chemically modified natural cellulose. It exhibits excellent thickening, film-forming, dispersibility, and water-retention properties, making it widely used in the textile printing and dyeing industry. CMC can be used as a printing paste, sizing agent, and auxiliary agent in the dyeing and finishing process, improving the quality of finished fabrics and production efficiency.

Application in Printing Pastes

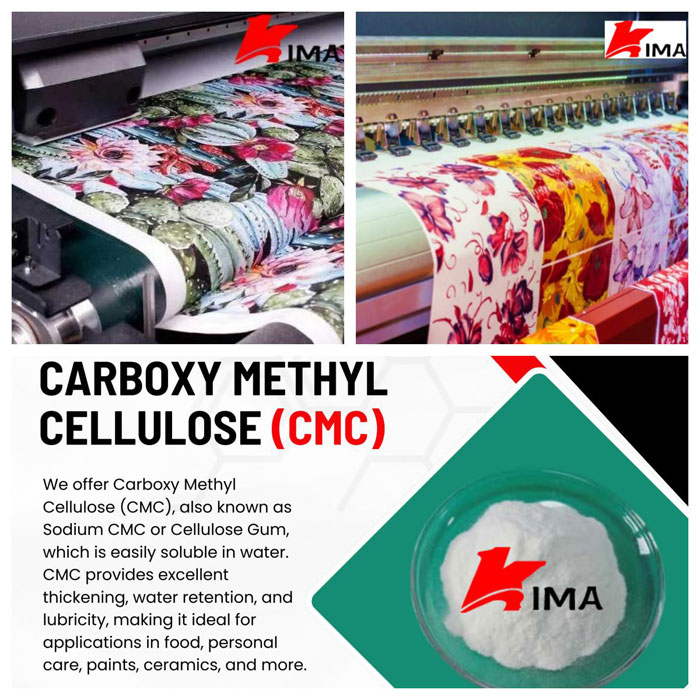

In the textile printing process, CMC is often used as a thickener and binder for printing pastes. Printing pastes require appropriate viscosity and rheological properties to ensure uniform distribution of the colorant on the fabric without bleeding. CMC solutions exhibit pseudoplastic rheological properties, meaning that their viscosity decreases under shear, facilitating transfer of the paste between the printing roller or stencil. Upon cessation of shear, their viscosity quickly recovers, preventing the outline of the pattern from spreading. This property results in sharp edges and uniform color in printed patterns. Furthermore, CMC exhibits excellent compatibility with most dyes, pigments, and auxiliaries, preventing precipitation or gelation, ensuring consistent printing quality.

Role in Fabric Sizing

During the sizing process before weaving, CMC can be used as a sizing agent or in combination with starch, PVA, and other agents. CMC forms a uniform film on the fiber surface, improving the yarn's abrasion resistance and tensile strength while reducing hairiness and end-of-breakage during weaving. Compared to traditional pure starch sizing, CMC sizing offers greater transparency and permeability, enabling even fiber coating and facilitating desizing, thus reducing the complexity of fabric post-processing. CMC's flexible film-forming properties can significantly improve weaving efficiency, particularly in high-density, fine-count yarn weaving.

Auxiliary Role in Desizing and Finishing

Although CMC is used in sizing, it can be easily decomposed and washed away with warm water or enzymes after weaving, resulting in efficient desizing without affecting subsequent dyeing and printing. In dyeing and finishing, CMC can also be used as a finishing agent in combination with softeners, anti-wrinkle resins, and other agents to improve the feel and appearance of fabrics.

Improved Dye Utilization

CMC can be used as a dye dispersant and suspension stabilizer during the dyeing process. For disperse dyes and vat dyes, CMC forms a protective layer in the solution, preventing dye particle aggregation and improving dyeing uniformity and permeability, thereby increasing dye uptake and reducing color variation.

Environmental and Economic Advantages

CMC is derived from natural cellulose and is highly biodegradable and environmentally friendly. Furthermore, a relatively low dosage can achieve excellent thickening and film-forming effects, reducing production costs. Compared to some synthetic polymer thickeners, CMC is more easily degraded during wastewater treatment, reducing COD load and promoting green production in the textile printing and dyeing industry.

Performance Optimization and Formulation Adjustment

In actual production, the degree of substitution (DS) and viscosity of CMC are key parameters. CMC for printing generally has a DS of 0.6–0.9 and a moderate viscosity to ensure color paste fluidity and film-forming properties. For sizing applications, higher viscosity grades can be selected to enhance yarn protection. CMC is often used in combination with synthetic thickeners, sodium alginate, and other agents to achieve a balance of rheological and film-forming properties, meeting the requirements of various textile processes.

CMC plays multiple roles in textile printing and dyeing: it is not only an ideal thickener and stabilizer for printing pastes, but also a highly effective yarn sizing agent and dyeing and finishing auxiliary. It also improves dye utilization, enhances the appearance and feel of fabrics, and offers environmental and cost advantages. With the textile industry's growing demand for green, efficient auxiliaries, CMC application prospects in textile printing and dyeing remain broad.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland