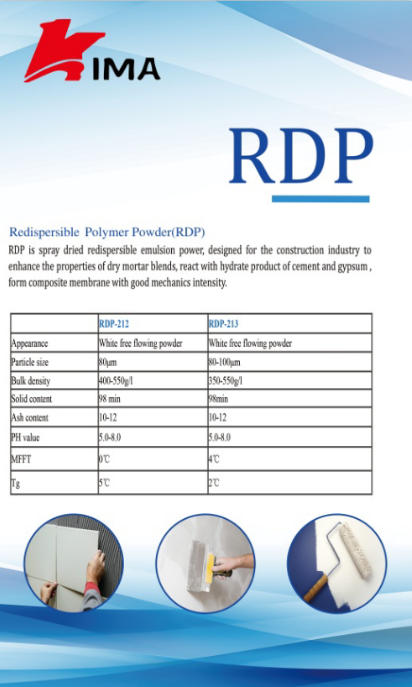

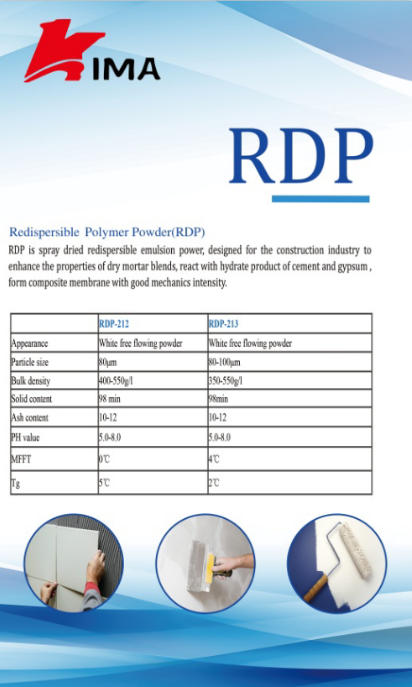

In modern building materials, redispersible polymer powder (RDP) is widely used in dry-mix mortar and plaster formulations. It is a high-molecular-weight polymer powder produced through a spray-drying process. Upon contact with water, it redisperses into a stable emulsion, restoring the properties of the original polymer emulsion. The introduction of RDP has significantly improved the workability and final product properties of plaster, making it a key additive for modifying traditional inorganic cementitious materials.

1. Enhanced Adhesion

One of the most critical properties in plaster construction is its bond strength to the substrate. Traditional cement plaster is prone to cracking or shedding due to drying shrinkage or temperature fluctuations. The polymer particles in RDP, during hydration, form a flexible organic film between the substrate and the plaster, enhancing adhesion and enabling the plaster to adhere firmly to a variety of substrates, including concrete, masonry, gypsum board, and even insulation board, reducing hollowing and shedding.

2. Improved Flexibility and Crack Resistance

Cement mortar alone is brittle and prone to stress concentration, leading to cracking, when subjected to temperature and humidity fluctuations. The polymer film formed by RDP dispersed in the mortar possesses a certain degree of elasticity, effectively relieving and distributing stress, improving the mortar's flexibility and extensibility. This not only enhances crack resistance but also allows it to adapt to slight deformations in the base layer, making it particularly suitable for applications requiring high flexibility, such as exterior wall insulation systems and lightweight walls.

3. Improved Water Retention and Workability

During construction, mortar requires a certain level of water retention to allow sufficient time for hydration of binders such as cement or gypsum. The addition of RDP synergizes with other water-retaining thickeners (such as HPMC) to increase the mortar's water retention, reduce premature water loss and shrinkage, and thus ensure workability, lubricity, and ease of handling. This makes it easier for applicators to apply, press, and level the mortar, resulting in a smoother, more even surface.

4. Enhanced Wear Resistance and Durability

The organic film formed by RDP not only offers excellent flexibility but also improves the density and wear resistance of the plaster surface. It reduces powdering and surface sand shedding after hardening, improving overall durability and service life. Furthermore, the polymer film provides protection for the plaster, resisting wind and rain erosion, freeze-thaw cycles, and slowing aging.

5. Improved Water Resistance and Impermeability

Although plaster is primarily composed of inorganic binders, it has a high porosity and is susceptible to water absorption and permeability. The continuous polymer film formed by RDP after hardening seals some of these pores, significantly improving impermeability and water resistance. This is particularly important for exterior wall plastering, bathrooms, and wet areas, where it helps enhance overall waterproofing.

6. Improved Impact Resistance and Additional Properties

RDP-modified plaster not only improves conventional mechanical properties but also enhances its impact resistance, making it less susceptible to breakage when subjected to external forces. In addition, depending on the polymer type, RDP can also impart other special properties to plaster, such as alkali resistance, UV resistance, and freeze-thaw resistance, expanding its application areas.

7. Synergy and Formulation Optimization

In plaster formulations, RDP is often used in combination with cellulose ethers (such as HPMC and HEC) and other fillers. RDP provides flexibility, adhesion, and durability, while cellulose ethers provide water retention and workability. The combination of these two can significantly optimize the plaster system, achieving an ideal balance between workability and long-term performance.

The main functions of RDP in plaster are:

Strengthening adhesion to the substrate, preventing detachment;

Improving flexibility and crack resistance, reducing cracking;

Improving water retention and workability, allowing for smoother application;

Enhancing wear resistance and durability, extending service life;

Improving water resistance and impermeability, making it suitable for exterior walls and humid environments;

Increasing impact resistance and imparting additional properties.

As an important organic modifier for plaster, RDP has become an indispensable additive in modern construction. It not only solves the brittleness and cracking problems of traditional inorganic plaster, but also improves the construction experience and quality of the finished product, providing buildings with a more stable, durable and beautiful surface effect.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland