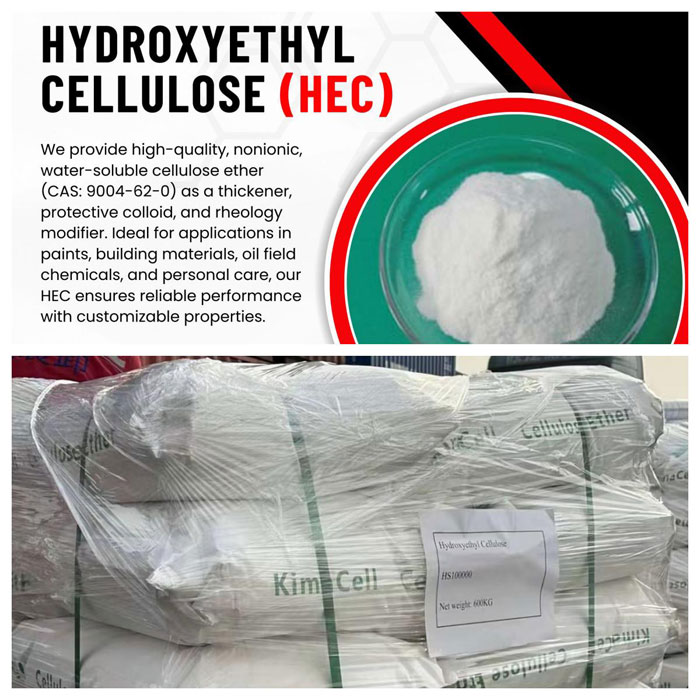

Hydroxyethyl Cellulose (HEC) is a nonionic, water-soluble cellulose ether widely used in coatings, construction, household chemicals, oil drilling, and other fields, primarily for thickening, stabilization, film-forming, and water-retention. Although HEC is chemically stable, its solution properties are significantly affected by pH. In practical applications, controlling the pH range not only helps maintain the solution's viscosity and rheological properties, but also extends the product's shelf life and performance.

HEC Stability at Different pH Levels

HEC is a nonionic polymer and, therefore, is not as pH-sensitive as anionic or cationic thickeners. However, its molecular chains are still susceptible to chemical degradation in extreme acidic and alkaline environments.

1.1. Acidic Conditions (pH < 4)

In strongly acidic environments, the ether bonds of HEC undergo acid-catalyzed hydrolysis, resulting in molecular chain breakage and a significant decrease in viscosity. Prolonged exposure to low pH can cause the solution to yellow, reduce clarity, and deteriorate rheological properties.

1.2. Neutral to Weakly Alkaline Conditions (pH 6–9)

This is the pH range in which HEC solutions are most stable. The molecular structure rarely breaks, and viscosity and thickening properties are maintained over time. Most coatings and household chemical formulations maintain a pH within this range.

1.3. Strongly Alkaline Conditions (pH > 10)

In a strongly alkaline environment, ether bonds are susceptible to alkaline hydrolysis or β-elimination reactions, accelerating molecular chain degradation, decreasing solution viscosity, and even causing dilution into water.

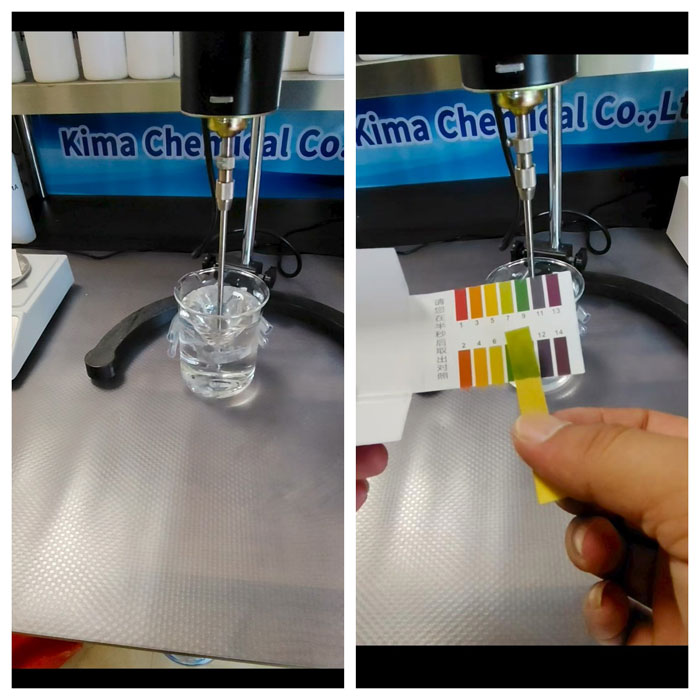

Effect of pH on the Dissolution Process

The HEC dissolution process consists of two stages: hydration and dispersion. pH affects the degree of stretching of its molecular chains in water.

Under neutral or weakly alkaline conditions, hydrogen bonds between molecular chains are moderately relaxed, facilitating water penetration and accelerating dissolution.

Under strongly acidic or alkaline conditions, while initial dispersion may be rapid, the final viscosity of the solution decreases due to molecular chain degradation.

In some applications (such as latex paints), pH adjustment is performed after HEC dissolution to control final rheological properties. In such cases, prolonged storage at high pH should be avoided.

pH Effect on Viscosity

HEC viscosity exhibits a stable-decreasing trend with pH changes.

pH 4–11: Viscosity changes minimally, suitable for most applications.

pH <4 or pH >11: Viscosity decreases significantly, with the rate of decrease accelerating with increasing temperature.

The rate of viscosity decrease in alkaline conditions is often faster than in acidic conditions, especially under high temperatures and shear. Therefore, special attention should be paid to alkaline coating systems.

pH Control Recommendations in Practical Applications

4.1. Coatings Industry

Water-based coating formulations often maintain a pH of 8–9 to balance emulsion stability and HEC thickening. If the pH is too high, a buffer or weak acid should be used.

4.2. Daily Chemical Products

Systems such as shampoo and body wash typically maintain a pH of 6–8, which not only promotes HEC stability but also maintains the pH balance of the skin and scalp.

4.3. Oil Drilling Fluids

Due to the complex downhole conditions, controlling the pH between 7–9 can extend the service life of HEC in drilling fluids.

4.4. Storage Considerations

Regardless of the industry, if HEC solutions require long-term storage, the pH should be kept away from extremes of acidity and alkalinity, and the temperature should be controlled to slow degradation.

pH is a key factor affecting the stability and performance of hydroxyethyl cellulose solutions.

Optimal Stability Range: pH 6–9

Acidic Risks: Hydrolytic degradation, viscosity loss, and color change

Alkaline Risks: Accelerated ether bond cleavage and a sharp drop in viscosity

When designing formulations, it is important to consider the effects of other components on pH and maintain pH stability during storage and transportation. Proper pH control not only maintains HEC thickening and rheological properties but also improves the overall quality and longevity of the product.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland