Ethyl cellulose (EC) is an etherified cellulose ether derivative. It exhibits excellent film-forming properties, water resistance, thermal stability, and chemical inertness, making it widely used in pharmaceuticals, food, coatings, inks, building materials, and other fields. Its main applications can be analyzed from the following perspectives:

Pharmaceuticals

Ethyl cellulose plays an important role in pharmaceutics and is often used as a controlled-release, sustained-release, and enteric coating material. Because it is insoluble in water but soluble in a variety of organic solvents, it can form dense films in the preparation of tablets, granules, and microcapsules, effectively controlling drug release rates, prolonging drug efficacy, and improving patient compliance. Ethyl cellulose is also used as a binder, film-forming agent, and matrix material, and is widely used in pharmaceutical formulations such as sustained-release tablets, oral thin films, and implants. Furthermore, EC plays a protective role in pharmaceutical coatings, isolating moisture and oxygen, enhancing drug stability, and preventing degradation of drug efficacy due to environmental influences.

Food Industry

In the food industry, ethyl cellulose wholesale is primarily used as an additive to provide film-forming, encapsulating, thickening, and stabilizing properties. It can act as a protective film on food surfaces, extending food freshness and preventing degradation due to evaporation or oxidation. EC can also serve as a flavor encapsulating agent, encapsulating flavors or nutrients, ensuring their stability during processing and storage, and gradually releasing them during digestion. Because ethyl cellulose is safe, non-toxic, and indigestible, it meets the standards for use as a food additive and is therefore also used in the production of functional foods, health supplements, and chewing gum.

Coatings and Ink Industry

Ethyl cellulose exhibits excellent film-forming properties, transparency, and mechanical strength, making it a common film-forming agent, thickener, and rheology modifier in coatings and inks. It forms a tough, smooth coating on substrates, providing abrasion resistance, chemical resistance, and moisture resistance. In the ink industry, EC is commonly used in gravure, screen printing, and hot-melt inks, improving ink adhesion and flow, enhancing the clarity and durability of printed products. In addition, ethyl cellulose's thermoplastic properties and good compatibility with various resins have led to its widespread use in plastic coatings and electrical insulating varnishes.

Building Materials and Industrial Applications

In construction chemicals, ethyl cellulose is used as an additive in waterproof coatings, sealants, and high-temperature resistant materials. It enhances the system's adhesion and durability, while also improving water resistance. In the processing of ceramics, metals, and glass products, EC is also often used as a temporary binder or molding aid. It burns and decomposes during high-temperature firing, without affecting the final product.

Plastics and Rubber

Ethyl cellulose can be blended with plastics and rubber materials to improve their processing and mechanical properties. Due to its thermal stability and flexibility, EC is often used as a plasticizer and toughening agent, making products more flexible and impact-resistant. It can also be used as a thermoplastic in hot-pressed products or as an adhesive.

Cosmetics and Daily Chemicals

In cosmetics, EC can be used as a film-forming agent and thickener in skincare, hairspray, mascara, and other products, enhancing their spreadability and film durability. Its non-toxicity, safety, and good skin tolerance make it widely applicable in daily chemical products.

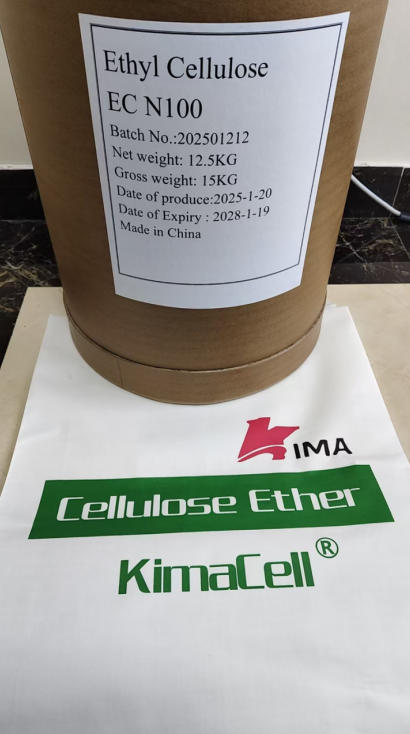

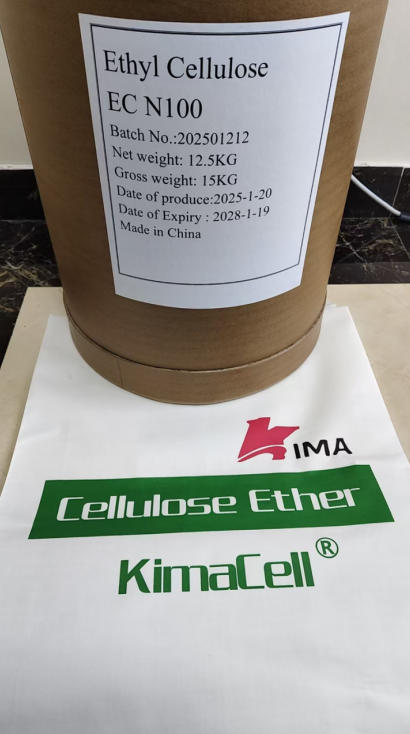

As a stable and versatile cellulose derivative, ethyl cellulose plays an important role in various industries, including pharmaceuticals, food, coatings, inks, building materials, plastics, and daily chemicals, thanks to its water insolubility, excellent film-forming properties, chemical inertness, and compatibility with various materials. With the growing demand for functional materials, cellulose ether manufacturers are expanding the applications of ethyl cellulose in novel drug delivery systems, environmentally friendly coatings, and high-performance functional materials, highlighting its even greater potential in the future.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland