Polyanionic Cellulose (PAC) is a water-soluble, cellulose-based polymer widely used in various industries, particularly in drilling fluids for the oil and gas sector. It is a chemically modified derivative of natural cellulose, where carboxymethyl groups are introduced into the cellulose backbone, rendering the material more hydrophilic and ionically active. PAC is highly valued for its excellent thickening, stabilizing, and water-retention capabilities, making it a versatile additive in a range of industrial and commercial applications.

Chemical Structure and Properties

PAC is derived from alkali cellulose, which undergoes etherification with monochloroacetic acid in the presence of sodium hydroxide. The carboxymethylation process replaces hydroxyl groups in the cellulose molecule with anionic carboxymethyl groups (–CH2–COONa), resulting in a water-soluble anionic polymer.

Key Properties:

Molecular Weight: Varies depending on the degree of substitution and polymer chain length.

Degree of Substitution (DS): Typically ranges from 0.4 to 1.0, affecting solubility and rheological behavior.

Solubility: Soluble in both hot and cold water; insoluble in organic solvents.

Viscosity: Available in low-viscosity (LV), regular-viscosity (RV), and high-viscosity (HV) grades.

pH Stability: Stable over a wide pH range (3–11).

Thermal Stability: Effective under moderate thermal conditions, usually up to 150°C in drilling fluids.

Types of PAC

There are generally two main commercial grades of PAC:

PAC-LV (Low Viscosity)

Primarily used for fluid loss control in drilling fluids without significantly altering viscosity. Suitable for high-density muds.

PAC-HV (High Viscosity)

Functions as both a fluid-loss reducer and a viscosifier. Provides suspension and improved hole cleaning in drilling operations.

Production Process

The production of PAC involves the following steps:

Preparation of Alkali Cellulose

Purified cellulose is treated with sodium hydroxide to produce alkali cellulose.

Etherification Reaction

The alkali cellulose is reacted with monochloroacetic acid or its sodium salt, forming carboxymethyl cellulose (CMC). Additional modifications with sulfonating agents introduce polyanionic functionality.

Purification

The resulting PAC is washed, neutralized, and dried to produce a fine powder or granular material suitable for industrial use.

Applications of PAC

Oil and Gas Drilling

PAC is most prominently used in the oil and gas industry as a key component in drilling fluids, completion fluids, and workover fluids.

Fluid Loss Control: PAC forms a thin, low-permeability filter cake on the borehole wall, reducing water loss to the formation and maintaining borehole integrity.

Rheology Modification: PAC-HV enhances the carrying capacity of the drilling mud by increasing viscosity, facilitating the removal of drill cuttings.

Shale Stabilization: The polymer interacts with clay minerals to prevent swelling and disintegration of shale formations.

Salt Tolerance: PAC remains effective in saline and brine environments, crucial for offshore and high-salinity formations.

Pharmaceutical Industry

PAC, due to its non-toxic and biocompatible nature, is used as a binder, disintegrant, and stabilizer in tablet formulations and suspensions. It helps improve drug release profiles and enhances the shelf-life of pharmaceutical products.

Food Industry

Although less common than other cellulose derivatives, PAC can be used as a thickening and stabilizing agent in sauces, gravies, and dairy products. Its water-holding capacity and viscosity modification are beneficial for texture and mouthfeel.

Cosmetics and Personal Care

In creams, lotions, shampoos, and toothpastes, PAC acts as a film-former, stabilizer, and viscosity enhancer. It improves the product's spreadability and contributes to its consistency and shelf stability.

Textiles and Paper

In the textile industry, PAC is used as a sizing agent to improve the strength and smoothness of yarns during weaving. In paper making, it functions as a retention aid and surface sizing agent, enhancing printability and reducing ink absorption.

Advantages of PAC

Excellent Water Solubility: Dissolves quickly in water, even at low temperatures.

Environmentally Friendly: Derived from renewable cellulose and generally regarded as non-toxic.

High Salt Tolerance: Performs well in brines and saline environments.

Thermal Stability: Retains performance under moderately high temperatures.

Low Dosage Effectiveness: Small quantities yield significant improvements in performance.

Limitations and Challenges

While PAC has numerous advantages, it also faces certain limitations:

Thermal Degradation: Though stable up to 150°C, PAC may degrade at higher temperatures unless chemically crosslinked or modified.

Biodegradability: Although natural-based, some PAC derivatives may persist in the environment depending on substitution level.

Cost: PAC is more expensive than some synthetic polymers, although its performance benefits can justify the price in critical applications.

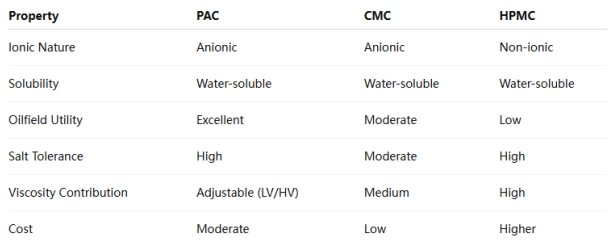

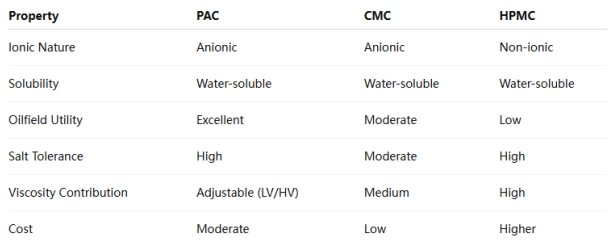

Comparison with Other Cellulose Derivatives

PAC is often compared with other cellulose ethers such as carboxymethyl cellulose (CMC) and hydroxypropyl methylcellulose (HPMC). While all three share cellulose as a base, they differ significantly in performance:

PAC is preferred in oilfield applications due to its superior performance in saline environments and better control over fluid loss.

Environmental and Safety Considerations

PAC is non-hazardous, biodegradable to some extent, and safe for handling under normal industrial conditions. Safety data sheets generally classify it as non-toxic and non-irritating. However, as with all powders, inhalation of dust should be avoided, and appropriate personal protective equipment (PPE) such as gloves and masks should be used during handling.

Future Outlook

With the increasing demand for sustainable and high-performance additives, PAC's role is expected to grow, particularly in eco-friendly drilling operations and biodegradable formulations. Innovations in crosslinking technology, nanocomposite integration, and bio-based modifications may further enhance PAC's thermal stability, biodegradability, and multifunctionality, making it even more attractive across sectors.

Polyanionic Cellulose (PAC) is a highly versatile, anionic cellulose derivative known for its exceptional performance in fluid retention, viscosity control, and salt tolerance. Its primary application in the oil and gas industry, especially in drilling fluids, has made it a critical material in energy exploration and production. Beyond this, its utility in pharmaceuticals, food, cosmetics, and paper underscores its multifunctionality. With ongoing innovations and a growing emphasis on sustainable materials, PAC is poised to remain a valuable polymer in modern industry.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland