Hydroxypropyl Methylcellulose (HPMC) is a non-ionic cellulose ether that is widely used in building materials, especially in tile adhesives. Due to its excellent physical and chemical properties and environmental friendliness, HPMC is widely used in the construction industry to improve construction performance, improve material stability and enhance bonding strength.

1. Basic properties of HPMC

HPMC is a polymer material made by chemical modification of natural plant cellulose. It has good water solubility, film-forming properties, thermal gelation and surface activity. It exhibits unique solubility and gelation at different temperatures, which makes it have excellent adaptability in the construction environment. In addition, HPMC is a non-toxic, tasteless, odorless green and environmentally friendly material that does not release harmful substances and is in line with the development direction of modern green building materials.

2. Advantages of HPMC in tile adhesives

Enhance water retention

Water retention is one of the key properties of tile adhesives. During the construction process, if the water evaporates too quickly, it will affect the cement hydration reaction, resulting in problems such as decreased bonding strength, hollowing, and brick falling. HPMC has a strong water retention capacity, which can effectively lock in moisture, ensure that the adhesive remains moist for a long time, and promote the full hydration of cement, thereby improving the final bonding strength and construction quality.

2.1.Improve bonding performance

HPMC can form a uniform polymer film in the colloid system to enhance the bonding between the tile adhesive and the base or tile. Especially in vertical construction or heavy brick and large brick construction, HPMC effectively prevents slippage, improves the hanging ability, and enhances the initial adhesion and final bonding strength by improving rheological properties and thixotropy.

2.2.Improve construction and operation time

HPMC gives tile adhesive excellent workability, making it easy to apply, spread and adjust the brick position during construction. At the same time, its excellent thixotropic properties make the material thinner when it is stirred or scraped by external force, which is conducive to construction; and it can quickly restore the consistency in a static state to prevent the tile from sliding down. In addition, HPMC can extend the open time, so that construction workers have more time to operate and adjust, improve work efficiency and reduce rework rate.

2.3.Optimize anti-slip performance

During the process of tile laying, especially vertical laying or large-scale tile construction, tile slippage is a prominent problem. HPMC can improve the anti-slip performance of tile adhesive, so that the tiles will not slide down due to gravity after pasting, ensuring the stability and beauty of the tile effect.

2.4.Improve the adaptability of the construction environment

HPMC has good adaptability to temperature and humidity. In high temperature or dry environment, tile adhesive is easy to lose water, while HPMC can effectively control the evaporation of water, keep the adhesive layer moist, and avoid bonding failure caused by cracking. In cold or humid environment, HPMC can also stabilize the colloidal structure, reduce the impact of freeze-thaw cycles, and ensure construction quality.

2.5.Improve the uniformity and anti-sagging of materials

HPMC can make the tile adhesive dispersed evenly and avoid stratification and segregation. At the same time, its improved rheological behavior gives the material good anti-sag properties, ensuring that the thickness of the adhesive layer is consistent during the construction process, and enhancing the uniformity and firmness of the bonding effect.

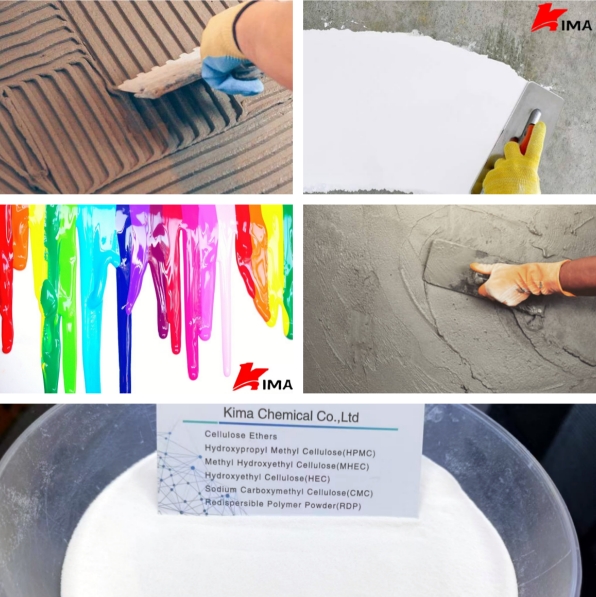

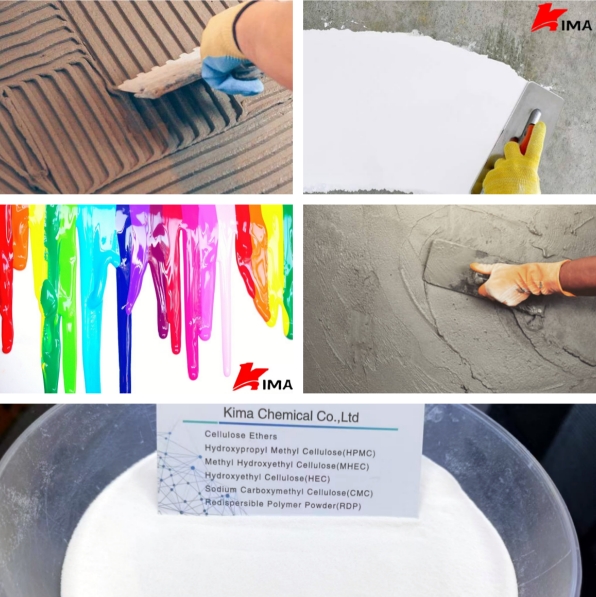

3. Advantages of HPMC in other building materials

In addition to its application in tile adhesives, HPMC is also widely used in construction fields such as putty powder, mortar, self-leveling, cement-based materials, etc., specifically as follows:

In putty powder, HPMC can improve water retention, improve construction smoothness and improve crack resistance.

In dry mortar, HPMC, as a thickener and water retainer, can improve construction efficiency and quality, and prevent problems such as cracking and powder loss.

In self-leveling materials, HPMC enhances the fluidity and stability of the material, ensuring flatness and hardening performance.

As a high-performance polymer additive, HPMC shows significant advantages in building materials, especially tile adhesives. It can not only significantly improve water retention, construction performance, adhesion and anti-slip performance, but also improve the overall stability and environmental adaptability of the material. As the construction industry's requirements for construction efficiency and material performance continue to increase, the application value of HPMC will become increasingly prominent, and it will play a more critical role in the field of green, energy-saving and environmentally friendly building materials in the future.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland