How HEC Improves Viscosity Control and Rheological Balance in Latex Paint Formulations

Hydroxyethyl cellulose (HEC) is one of the most widely used rheology modifiers in water-based latex paint formulations. Its primary function is to provide precise viscosity control while maintaining a balanced rheological profile that supports both storage stability and excellent application performance. Through its unique molecular structure and hydration behavior, HEC plays a critical role in ensuring that latex paints exhibit consistent flow, leveling, and resistance to defects during and after application.

One of the key advantages of HEC lies in its ability to hydrate uniformly in water, forming a three-dimensional polymer network that increases viscosity efficiently at relatively low dosages. This network thickens the aqueous phase of latex paint systems, allowing formulators to achieve target viscosity without negatively affecting solids content or film-forming properties. By adjusting the molecular weight and degree of substitution of HEC, paint manufacturers can fine-tune viscosity across different shear rates, from low-shear storage conditions to high-shear application processes such as brushing, rolling, or spraying.

HEC also provides a favorable pseudoplastic, or shear-thinning, rheological behavior. Under low shear, such as during storage, the viscosity remains sufficiently high to prevent pigment settling and phase separation. When shear is applied during mixing or application, the polymer chains temporarily align and disentangle, resulting in a rapid viscosity drop. This behavior improves paint flow and ease of application, reduces splattering, and allows for smooth spreading on substrates. Once shear is removed, HEC quickly rebuilds viscosity, helping the paint maintain film thickness and minimize sagging on vertical surfaces.

Another important contribution of HEC to rheological balance is its compatibility with a wide range of latex binders, pigments, and additives. HEC is non-ionic, which makes it less sensitive to pH variations and electrolyte content commonly found in latex paint formulations. This stability ensures predictable viscosity development and minimizes the risk of viscosity drift during storage or after tinting. As a result, formulators can achieve consistent batch-to-batch performance and long-term shelf stability.

HEC supports better leveling and surface appearance by controlling flow after application. The balanced rheology provided by HEC allows the paint to spread evenly before drying, reducing brush marks and roller patterns. At the same time, excessive flow that could lead to sagging or dripping is effectively controlled. This balance between flow and structure is essential for achieving high-quality finishes in architectural and industrial latex paints.

HEC improves viscosity control and rheological balance by combining efficient thickening, shear-thinning behavior, and excellent formulation stability. These characteristics make HEC an indispensable additive for latex paint systems that demand reliable processing, easy application, and superior final appearance.

The Role of HEC in Pigment Dispersion, Anti-Settling Behavior, and Storage Stability

Hydroxyethyl cellulose (HEC) plays a vital role in maintaining pigment dispersion, preventing settling, and ensuring long-term storage stability in latex paint formulations. As a water-soluble, non-ionic cellulose ether, HEC functions not only as a thickener but also as a key stabilizing agent that supports uniform color development and consistent performance throughout the product's shelf life.

One of the primary challenges in latex paint formulation is achieving and maintaining even pigment dispersion. Pigments and fillers tend to agglomerate due to their high surface energy, which can lead to color inconsistency and poor hiding power. When properly hydrated, HEC increases the viscosity of the aqueous phase and creates a structured polymer network that helps keep pigment particles evenly suspended. This network reduces particle mobility, limiting re-agglomeration after high-speed dispersion and during subsequent storage.

HEC also contributes to improved wetting and distribution of pigments during the grinding and mixing process. Although dispersants are the main agents responsible for pigment wetting, HEC complements their function by stabilizing the dispersed state once achieved. The non-ionic nature of HEC minimizes adverse interactions with anionic dispersants or surfactants, ensuring that pigment particles remain well separated and uniformly distributed within the latex system.

Anti-settling performance is another critical benefit of HEC in latex paints. During storage, gravity-driven sedimentation can cause heavy pigments and fillers to settle at the bottom of the container, leading to hard settling that is difficult to re-disperse. By increasing low-shear viscosity and yield value, HEC effectively slows down sedimentation rates. The resulting soft-settling behavior allows any settled material to be easily re-incorporated with minimal stirring, improving user convenience and reducing product waste.

In addition to preventing pigment settling, HEC enhances overall storage stability by maintaining a consistent rheological profile over time. Latex paints may experience viscosity changes due to temperature fluctuations, pH shifts, or interactions between formulation components. HEC's chemical stability and resistance to enzymatic degradation help minimize viscosity loss and phase separation during prolonged storage. This stability is particularly important for tinted paints, where added colorants and electrolytes can otherwise disrupt rheology.

HEC helps prevent syneresis and water separation in latex paints by strengthening the internal structure of the liquid phase. A well-balanced HEC system ensures that the binder, pigments, and additives remain uniformly distributed, preserving the paint's appearance, application properties, and performance even after long storage periods.

HEC plays a crucial role in pigment dispersion, anti-settling behavior, and storage stability by building a stable viscosity structure, supporting dispersed pigment systems, and reducing sedimentation. These benefits make HEC an essential component in high-quality latex paints that require reliable shelf life, consistent color, and easy re-dispersion before application.

HEC Contribution to Flow, Leveling, Brushability, and Roller Application Performance

Hydroxyethyl cellulose (HEC) is a key rheology modifier that significantly influences the application behavior of latex paints. Beyond basic viscosity control, HEC helps achieve an optimal balance between flow, leveling, and structural stability, directly affecting brushability and roller application performance. These properties are essential for producing smooth, uniform coatings with minimal defects on a wide range of substrates.

Flow and leveling are closely related to how a paint spreads and smooths out after application. HEC provides controlled shear-thinning behavior, allowing the paint to flow easily under the shear forces generated by brushing or rolling. During application, the viscosity decreases temporarily, enabling the paint to spread evenly across the surface without excessive drag. Once the shear is removed, HEC rapidly rebuilds viscosity, allowing the wet film to level smoothly while preventing over-flow that could cause sagging or dripping.

Brushability is another area where HEC delivers clear benefits. Paints formulated with properly selected HEC grades exhibit reduced brush resistance and improved glide, making application more comfortable and efficient for both professional painters and DIY users. The uniform rheological profile created by HEC helps the paint load evenly onto the brush and release consistently onto the substrate. This minimizes brush marks, lap lines, and streaks, resulting in a more uniform and aesthetically pleasing finish.

For roller application, HEC contributes to excellent pick-up, transfer, and spatter control. Adequate low-shear viscosity ensures that the paint is effectively loaded onto the roller without dripping, while shear-thinning behavior allows smooth transfer to the wall or ceiling. HEC also helps reduce roller spatter by maintaining sufficient film cohesion during high-speed rolling, preventing paint droplets from being thrown off the roller. At the same time, the paint spreads evenly, producing a consistent film thickness across large surface areas.

HEC further enhances application performance by improving edge coverage and open time. The controlled water retention provided by HEC slows down premature drying, allowing painters more time to work the paint and blend edges seamlessly. This is especially important in warm or dry conditions, where rapid water loss can lead to poor leveling and visible application marks. By maintaining a stable wet film, HEC supports smooth flow and continuous leveling before film formation is complete.

HEC compatibility with common latex binders and additives ensures predictable application behavior across different formulations. Its non-ionic nature minimizes sensitivity to pH and electrolytes, helping maintain consistent flow and leveling even after tinting.

HEC contributes significantly to flow, leveling, brushability, and roller application performance by providing shear-responsive rheology, stable film formation, and controlled water retention. These characteristics help latex paints achieve smooth application, reduced defects, and high-quality surface finishes across a wide range of application methods.

Selecting the Right HEC Grade for Different Latex Paint Systems and End-Use Requirements

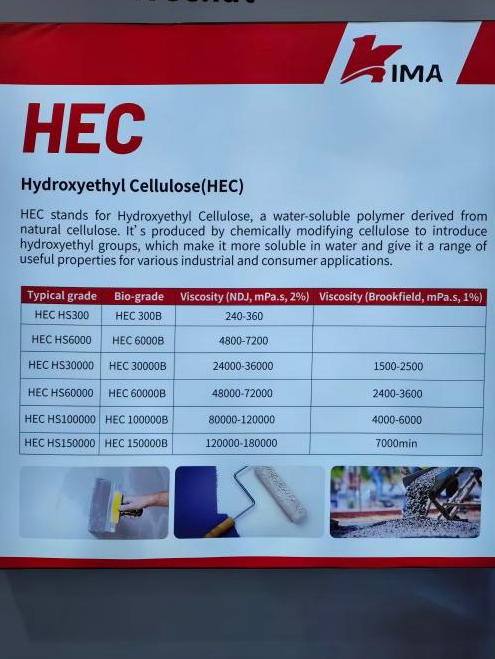

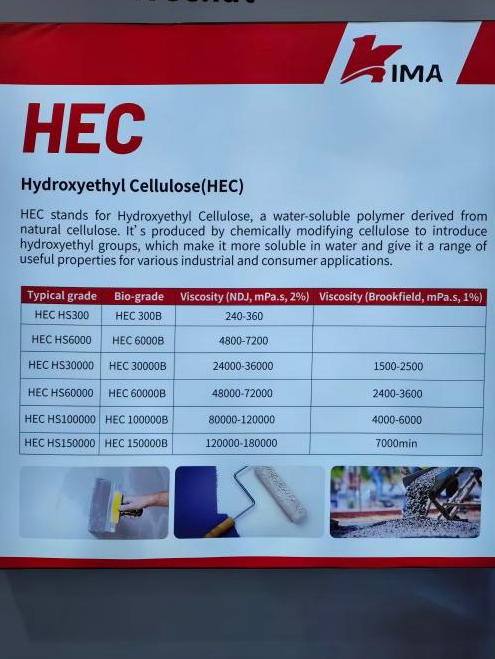

Choosing the appropriate hydroxyethyl cellulose (HEC) grade is a critical step in designing high-performance latex paint formulations. Different latex paint systems and end-use requirements demand specific rheological profiles, application behaviors, and stability characteristics. By carefully selecting HEC based on its molecular weight, viscosity grade, and solubility characteristics, formulators can optimize paint performance from production to final application.

One of the primary criteria in HEC selection is viscosity grade, which is closely related to molecular weight. High-viscosity HEC grades are typically used in interior and exterior architectural paints that require strong anti-settling properties, good sag resistance, and stable storage performance. These grades build higher low-shear viscosity and yield value, making them suitable for flat and matte finishes where pigment loading is high. In contrast, medium- to low-viscosity HEC grades are often preferred for semi-gloss and gloss paints, where better flow, leveling, and surface smoothness are essential.

Latex binder type also plays an important role in HEC selection. Acrylic, styrene-acrylic, and vinyl acetate-based emulsions can respond differently to thickener systems. HEC's non-ionic nature generally ensures broad compatibility, but certain binders may require tailored HEC grades to achieve the desired rheological balance. For example, paints designed for high-shear application methods such as spraying often benefit from HEC grades that provide sufficient viscosity at rest while allowing rapid shear thinning during application.

End-use requirements further influence HEC grade choice. For interior wall paints, emphasis is often placed on smooth brushability, low spatter, and good leveling. Medium-viscosity HEC grades with balanced hydration rates are commonly selected to meet these needs. For exterior paints, where temperature variations, longer storage periods, and higher durability are expected, more robust HEC grades with strong viscosity retention and resistance to degradation are preferred.

Another important factor is HEC solubility and hydration behavior. Fast-dissolving HEC grades can simplify manufacturing processes and reduce mixing time, making them suitable for high-efficiency production lines. Delayed-solubility or surface-treated HEC grades, on the other hand, help prevent lump formation during dispersion and allow better control over viscosity build, especially in one-step addition processes.

Regulatory and environmental considerations may also affect HEC selection. Low-odor, low-VOC latex paints often rely on HEC grades that perform well in simplified formulations with fewer co-additives. Consistency after tinting is another key requirement, as selected HEC grades must maintain stable viscosity even when colorants and electrolytes are introduced.

Selecting the right HEC grade requires a comprehensive understanding of latex paint systems, application methods, and end-use expectations. By matching HEC viscosity, compatibility, and hydration characteristics to specific formulation needs, manufacturers can achieve optimal performance, consistent quality, and superior end-user satisfaction across a wide range of latex paint applications.

English

English 日本語

日本語 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية Türkçe

Türkçe Nederland

Nederland